We deliver sustainable Engineering solutions and services to various industries within Nigeria.

Our partners and clients value us for the quality of our services.

- Client : The Nigeria Petroleum Development Company (NPDC)RPC)

- Services :Engineering, Procurement, Construction, & Installation Services.

- Location :OML 119, Okpoho-Okono Field, Offshore Nigeria

- Status :Ongoing

- Total Man-hours :

- Safety Records :

Okpoho-Okono 12'' & 6'' Subsea Flexible pipelines EPCIC Project

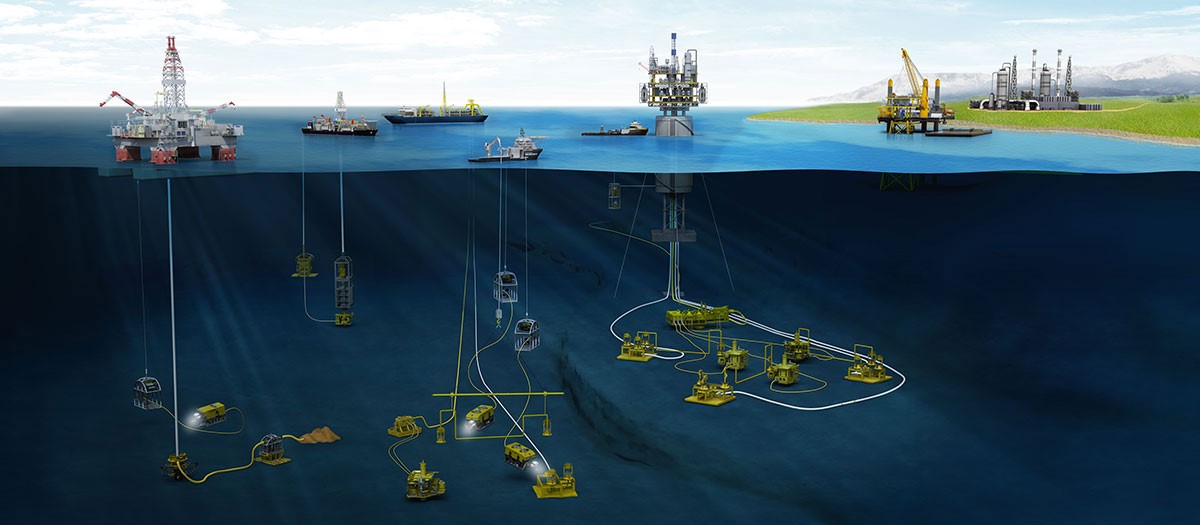

Okono and Okpoho fields are located offshore Nigeria in OML119 block, 55 km from Shell’s Bonny Oil Terminal, in a water depth ranging from 65 to 100 m. The field produces oil and gas through the Mystras FPSO.

NPDC embarked on the replacement of the existing rigid 16'' Multiphase crude line and 8" Gas lift pipelines with flexible 12'' and 6'' Pipelines after the conclusion of FEED studies. The contract was awarded to Melcurt limited for the EPCIC of the new pipelines.

Project Scope

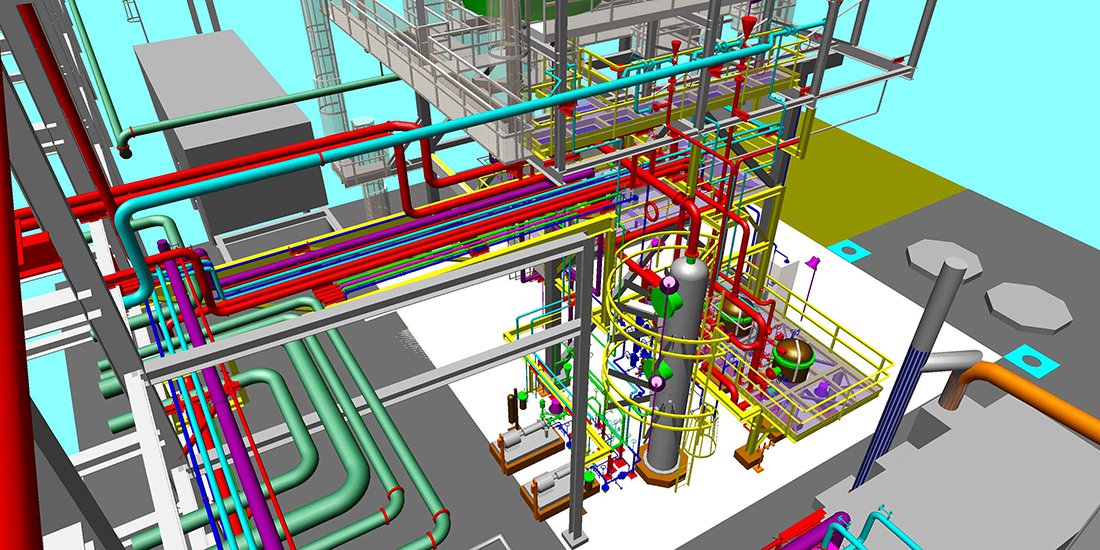

Melcurt's Scope of work includes FEED verification, detailed Engineering Design, Procurement of 12'' and 6'' flexible pipelines with Subsea Safety Isolation Valves (SSIVs), Transportation and offshore installation of Flexible pipelines & SSIVs, Tie-in/Hook-up to the Mystras FPSO and Okpoho Well head platform (WHP), FPSO and WHP topsides modification, Pre-commissioning, Commissioning and Hand-over.

Detailed Engineering Design is underway in Nigeria with the manufacturing of the Flexible pipelines and SSIVs taking place in Denmark and Brazil. offshore installation is scheduled to take place Q1 2021.

- Client : SHELL PRODUCTION DEVELOPMENT COMPANY (SPDC)

- Services :Construction, Dredging & Installation services.

- Location :Bayelsa, Nigeria

- Status :Completed Q3 2018

- Total Man-hours :Over 16,500

- Safety Records :Zero LTI, Zero MTI

16'' NUN RIVER PIPELINE INSTALLATION PROJECT

SPDC had reported a Leak on the Nun River Trunk line at Ekoli section and Contracted MELCURT NIGERIA to perform sectional replacement for the entire river crossing & salvage the old section of the pipeline.

What We Did

The first challenge stemmed from the very fast current of the river at the Upstream section of the LBV station, which led to the damage of the existing pipe section, and hence a threat to the proposed pipeline to be installed. MELCURT successfully salvaged the old Pipeline section, Dredged the river to meet the required installation profiles and successfully installed the 16’’ Pipeline by River Crossing. Melcurt Nigeria, in a bid to provide stability for the pipeline from the river current, installed about 100 concrete mattresses as required by the client.

Final Results

The projects was completed and turned over to SPDC having successfully salvaged the old section, Installed and commissioned the new pipeline, and provided stability of the installed pipeline from further damage by rogue river current

- Client : SHELL PRODUCTION DEVELOPMENT COMPANY (SPDC)

- Services :Engineering, Procurement, Construction, & Installation Services.

- Location :Odidi, Nigeria

- Status :Completed Q4 2018

- Total Man-hours :Over 424

- Safety Records :Zero LTI, Zero MTI

16 INCH x 26Km FORCARDOS NORTH BANK - ODIDI AGG PIPELINE

The 16 inch x 26Km Forcados North-Bank to Odidi AGG Pipeline was constructed in the year 2004 with the intend to evacuate gas from FYIP – EGGS. Pre-Commissioning was done February 2018 on the pipeline and a caliper run was conducted in April 2018 confirming the pipeline was dented about 1.5Km close to the Odidi CPF Platform and a leak point also confirmed on the nearest bend.

What We Did

The scope of work was to carry out a permanent repair using Cofferdam on two points on the 16” X 26km North Bank Forcados Odidi AGG Pipeline. Some of the major challenges were tidal changes, the presence of underground facilities and disused manifold within site layout and unfriendly weather conditions.

Final Results

The project was successful in record time, allowing the client to start-up the pipeline for Gas transportation.

- Client : WARRI REFINING AND PETROCHEMICAL COMPANY LIMITED (WRPC)

- Services :Engineering, Procurement, Construction, & Installation Services.

- Location :Warri, Nigeria

- Status :Completed Q2 2016

- Total Man-hours :Over 13,600

- Safety Records :Zero LTI, Zero MTI

INSTALLATION OF 24”x 480M PMS PIPELINE (PUMP HOUSE “C” TO TANKS 301-TK-43/44).

The WRPC 24” PMS pipeline has several leakages which poses high risk of PMS spills, and pollution between the pump house ‘c’ to tank 43/44 pipeline area. Hence MELCURT LIMITED was contracted by WRPC to carry out pipeline replacement/installation to restore it back to standard.

What We Did

The scope of work was to carry out a permanent repair by replacement/installation on the leak areas. This was done but Inspite of flushing there was still consistent emission of gas during salvaging. As a result, WRPC fire fighting team were mobilized to the highly volatile areas for quick response in case of fire outbreak. Some sections of the pipeline were clustered as a result of many pipeline passing through the same right of way thereby making the work area unconducive. Some of our major successes were involvement of personnel from mobilization stage without fatality showed good management coordination. We maximized the opportunity of the project to develop the host community workers. We worked without polluting the environment.

Final Results

The replacement/installation project was successfully carried out and the pipeline has been restored to normal standard as required.